Trucking’s fuel efficiency is not just about choosing one or two main parts. It is facilitated collaboratively by several technical aspects: sheet metal, vehicle aerodynamics, type of transmission, axle configuration, rolling resistance, and driver behavior, among others. It is often the case that just like people drive for earning these important tips, the actual return is beneficial only when one decides on a full set of specific vehicle components.

It is the systems-based method, not the occasional one, that can bring down fuel costs sustainably.

Fuel prices are one of the major uncertain cost factors in the trucking industry, but the decrease in fuel consumption is not optional anymore. It not only has direct consequences on profit and route competitiveness but also is a factor in the fleet’s sustainability in the long term. In this article, the discussion will be truck aerodynamicures, the type of transmission used, axle setups, and powertrain optimization which are actual mechanics of heavy-duty truck fuel economy — instead of misleading marketing.

Fuel Efficiency Functions as a System Rather Than a Single Improvement

Fuel efficiency is often misperceived as an addition from the outside. This systems-based understanding of fuel efficiency is also reflected in independent industry research, including analyses by the Union of Concerned Scientists, which identify aerodynamics, drivetrain efficiency, transmission design, and rolling resistance as the primary drivers of fuel consumption in heavy-duty trucks.(Source: Union of Concerned Scientists — Heavy-Duty Truck Fuel Efficiency)

However, every truck exhausts fuel due to multiple factors occurring simultaneously such as drag, friction, drivetrain inefficiencies, rolling resistance, and excess RPM. As a rule, benefits from any kind of alteration in just one area without consideration of the others will be inferior.

Most of the time, any improvement to single areas without regard to other departments just results in despair.

For fleets and drivers to bring down fuel consumption effectively, they need to zero in on:

- Proper airflow management around the tractor and trailer

- Good engine power transfer through the drivetrain

- The engine speed must be appropriate relative to the torque demand

- Tire efficiency and pressure stability

- Correct axle loading and weight distribution

All these factors are factors in terms of vehicle performance that dictate fuel costs. The difference between the two is that at the prior stage the truck is treated as a whole system instead of being broken down into separate components.

Semi-Truck Efficiency: 14 Ways to Save Money on Fuel

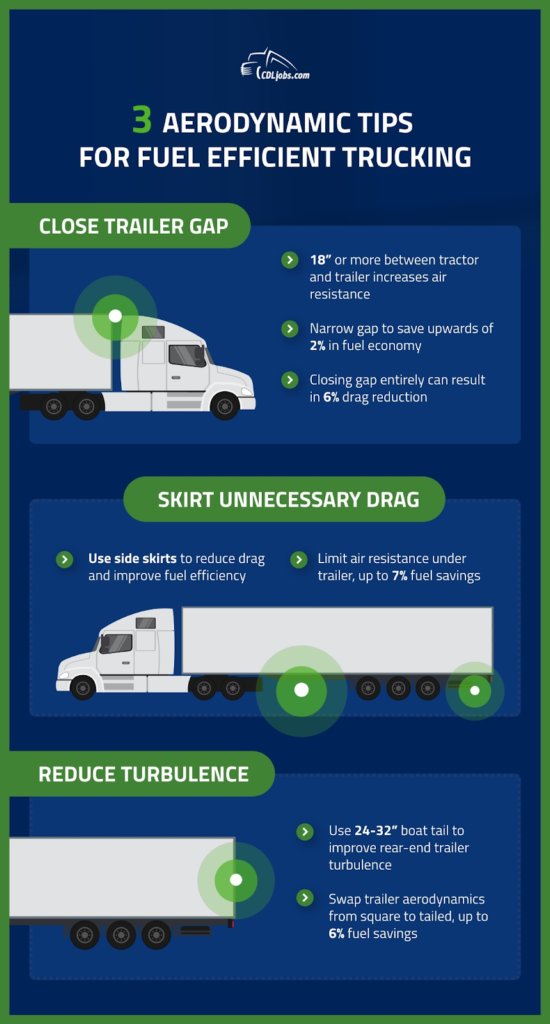

Truck Aerodynamics: The Major Fuel Loser

When the truck is at high speed, truck aerodynamics totally dominate the fuel-wasting and expense factors. Aerodynamics of the truck only get into trouble when the rolling resistance is the only cause of losses. By contrast, at cruising speed, the aerodynamic drag is by far more relevant than the rolling resistance and the mechanical losses put together.

With bad aerodynamics, the engine will have to work much harder to maintain the speed. A slight misalignment in airflow will accumulate over the years causing thousands of dollars in losses due to fuel. The right aerodynamic components are then critical.

11 MPG in a Class 8 Truck? Here’s How Joel Does It

The Most Important Parts of the Aerodynamics

Modern aerodynamic devices are devised with the functionality of air running efficiently and comfortably, rather than forcing air to align:

- Roof fairings align airflow between tractor and trailer heights

- Side skirts eliminate the turbulence beneath the trailer

- Trailer tails reduce rear low-pressure drag

Only if and only if, these devices are combined rightly, you can expect regular savings of 5–10% fuels on major roads, thereby making aerodynamics the most effective individual category for optimizing fuel efficiency in long-haul trucking.

The Addition of Aerodynamic Devices to Fuel-Efficient Driving

Nevertheless, even the most carefully engineered aerodynamics setup cannot compensate for aggressive driving. Fuel-efficient driving means, among others, that drivers should be on a steady throttle input, controlled acceleration, and anticipate traffic rather than to be in a rush.

Drivers who are conscious of drag reduction have the ability to instinctively develop walking habits that prefer to protect the machine efficiency more than undermining it.

Transmission Type and Drivetrain Efficiency

Transmission type is an important factor in supplying the engines energy to the wheel efficiently. The objective is to have the engine operate continuously in the desired RPM band.

Manual transmissions of course offer proficient drivers a chance to save fuel, but the results are inconsistent. Automated Manual Transmissions (AMTs) eliminate variability and are generally considered the best choice for fuel economy across the range of drivers. Full automatic transmissions which are usually preferred for comfort may lower the highway efficiency slightly.

Kenworth Connects Episode 1: Fuel Economy

Axle Ratio: A Little Number That Makes a Big Difference

Axle ratio selection is one of the least recognized problems in truck specification. It indicates the number of times the engine will have to rotate in order to turn the wheels to a specified speed.

Lower numerical ratios decrease highway RPM and support the savings, at the same time higher ratios increase the pulling power by the disfavor of fuel economy. The correct axle selection is the key for proper powertrain optimization.

Single Axle vs Tandem Axle: Efficiency or Payload

The decision regarding single axle versus tandem axle affects the weight, rolling resistance, and drivetrain losses.

The single axle setups are lighter and more fuel-efficient than tandem axles, while this case just provides the advantage of tandem axles – traction and payload capacity which come at a higher cost of fuel. Fuel efficiency must always be analyzed concurrently with the revenue potential and should never be looked at as an isolated variable.

Tires, Rolling Resistance, and Fuel Efficiency Technologies

Low rolling resistance tires significantly reduce energy lost through deformation and friction. Poorly inflated tires quickly counters any aerodynamic and drivetrain advantages.

The new generation of fuel-saving technology is almost entirely based on tire pressure monitoring systems that are corrective to tire inefficiency during long-running distances.

Powertrain Optimization: Making Everything Work Together

True efficiency emerges only when all components: aerodynamics, transmission, axle ratio, tires, and engine characteristics work like a team. Any misalignment in one part will lower the total performance.

A powertrain that is effectively tuned allows the truck to hold speed with less throttle input which ultimately results both in gas savings and longer run time for the engine.

Practical Fuel Savings Beyond Hardware Choices

Although the hardware decisions are the core ones, the amount of fuel that can be saved daily in operations also relies on the extent to which these decisions are applied in practice. A truck, which has even the best configuration, will lose its efficiency if the drivetrain is not operating at full efficiency or if the driving habits neutralize some of the vehicle built-in advantages. Tips that have a real impact in reducing fuel costs, including fuel saving tips used by experienced operators, mainly center on the operator’s awareness of the system than on feeling shortcuts. Over time, if you monitor your drivetrain efficiency, you can identify the times when the mechanical resistance is up, and if you respond to them early, you can prevent the slow depletion of fuel resources that, otherwise, mostly go unnoticed. Fuel economy technology is becoming increasingly important, especially the tools that give feedback on engine load, gear selection, and rolling resistance trends. The question of single axle vs tandem axle should also be considered beyond just the payload aspects. In fuel-conscious operations, the operator that knows the right time to use a tandem axle and the time it merely adds to the rolling resistance should take a strategic decision of balancing profit or increase fuel consumption in the long run. In particular, the wise decision on the axles combined with driving discipline can be a decisive factor in saving fuel more effectively than perfecting a truck with isolated upgrades.

Hence, the green fuel saving is not a matter of a one-off act but rather of the continued agreement between the vehicle design, the fuel economy technology, the drivetrain efficiency, and the decisions taken mile by mile.

Fuel-Efficient Driving is Always Important

The technology cannot replace the conventional behavior of getting the job done right. Gentle acceleration, steady cruising, and anticipation of traffic save every mechanical advantage that has been engineered into the truck.

Drivers who have been well versed in truck specification and how it corresponds to real-world road conditions have a greater chance of achieving better fuel outcomes.

Fuel Efficiency Factors at a Glance

| Component Area | Impact on Fuel Economy | Typical Savings |

| Aerodynamic components | Reduced highway drag | 5–10% |

| Transmission type | Optimized RPM control | 2–5% |

| Axle ratio selection | Lower cruising RPM | 1–4% |

| Low rolling resistance tires | Reduced friction losses | 1–3% |

| Fuel-efficient driving | Preserves system efficiency | Variable |

Single Axle vs Tandem Axle Comparison

| Configuration | Fuel Efficiency | Payload Capacity | Best Use Case |

| Single axle | Higher | Lower | Regional, light freight |

| Tandem axle | Lower | Higher | Heavy loads, traction-critical routes |

FAQ: Fuel Efficiency, Aerodynamics, and Drivetrain Choices

Does aerodynamics matter at lower speeds?

Yes, but its impact increases significantly at highway speeds where drag dominates fuel loss.

What is the best transmission for fuel economy?

AMTs generally provide the most consistent fuel savings across fleets.

Can axle ratio changes alone reduce fuel consumption?

Only when matched to the route type, speed, and load weight.

Are low rolling resistance tires worth it?

Yes, when properly inflated and matched to the application.

Is fuel-efficient driving still important with modern technology?

Absolutely. Driving behavior amplifies or negates mechanical efficiency.

Final Thoughts

Spending less fuel in trucking is not about following trends or relying on singular upgrades. Instead, it is the understanding of how truck specification, aerodynamics, transmission type, axle configurations, tires, and driving habits all mesh together.

Fuel efficiency is the intersection between engineering and self-discipline. Fleets and drivers who see it as a system save on fuel, get better vehicle performance and protect their long-term profitability — trip after trip. In the long run, consistent fuel savings come from informed decisions applied every mile, not from one-time technical changes.

That discipline, once built into daily operations, becomes one of the most reliable competitive advantages in trucking.