In trucking arrangements, the acceptance of a rate is usually not equivalent to profitability. Much earlier decisions of its shaping the decision about the final financial result of a shipment are mainly based on the procedures like the assigning of equipment concerning the specific loads and delivery windows. The transportation of even a well-priced load can steer the driver to an extra mile due to the lack of an adequate load bank, as it should be the case, whereas the driver gets punished with a timeout for not being able to carry out the job.

Equipment assignment is not merely the clerical step or the dispatch shortcut. It is the central logistics process which, through direct influence on asset utilization, delivery reliability, maintenance exposure, and driver performance determines how the fleet performs. A systematic approach towards equipment assignment allows the fleets to optimize operations, bring stability to scheduling, and achieve logistics optimization even in volatile freight cycles.

The Load as the Starting Point for Equipment Assignment

One of the most frequently made mistakes in fleet management is making decisions based on availability. When dispatch kicks off with “Which truck is free?” instead of “What does this load require?”, inefficiencies stack throughout the organization.

Every load has its unique operational fingerprint. According to logistics optimization practices, matching available trucks and their capacity with cargo volume, delivery routes, and other factors significantly improves asset utilization and reduces empty miles, confirming that proper load-driven equipment selection is crucial for efficient trucking operations. Fleetx

The loads vary not just in weight but also in terms of cargo sensitivity, dimensions, handling constraints, stop frequency, and route complexity. These factors define the need for load specific equipment, ensuring that execution happens without forcing compensations in other operational areas.

For instance, loading a lightweight product with numerous urban stops and the requirement of a very short time of delivery often needs high maneuverability, quick braking, and simple but fast dock handling. In the case of such assignments, transportation equipment designed for long highway runs will not only increase the spent fuel but also result in delayed appointments and fatigued drivers. On the opposite hand, heavier loads that are on high-speed roads for a longer time do benefit from equipment designed for stable cruising and load balance.

The correct pair of load and equipment is the one that makes trucks and trailers really support execution, as opposed to drivers and dispatchers getting forced to adapt to mismatched equipment, which is the core principle of optimal equipment selection.

Relationship Between Load Characteristics and Equipment Requirements

| Load Factor | Operational Impact | Equipment Implication |

| Payload weight | Stress on drivetrain and braking | Axle configuration and suspension selection |

| Cargo sensitivity | Risk of damage | Suspension type and load securing |

| Stop frequency | Increased wear | Brake capacity and maneuverability |

| Route complexity | Time variability | Turning radius and visibility |

| Handling requirements | Dock efficiency | Trailer access and positioning |

Equipment Windows as a Structural Constraint in Planning Equipment

Delivery windows are often treated as mere scheduling notes instead of being operational constraints that are hard. In fact, the delivery windows set the rhythm of execution and they should define the whole equipment allocation procedure.

The effect of tight delivery windows on:

- Acceleration and braking patterns

- Maneuverability in confined yards and city zones

- Driver hours of service alignment

- Buffer capacity for inspections, traffic, and delays

Selecting appropriate delivery window equipment is critical for maintaining schedule integrity and avoiding cascading delays across the route. Equipment that performs efficiently in flexible schedules might find it difficult to function with accurate timing involved. A long wheelbase, a heavy axle configuration, or a slower-load setup could possibly be the causes for an insignificant delay turning into an appointment being missed.

The successful delivery scheduling system emphasizes clarity and control, particularly in the case of regional, urban, and appointment-driven freight.

Delivery Window Constraints and Equipment Sensitivity

| Delivery Constraint | Operational Risk | Equipment Sensitivity |

| Narrow appointment windows | Missed delivery | Dock handling speed |

| Urban delivery zones | Access delays | Turning radius |

| Night or restricted hours | Compliance risk | Noise and maneuverability |

| High stop density | Fatigue accumulation | Brake and suspension durability |

| Limited buffer time | Schedule collapse | Reliability and predictability |

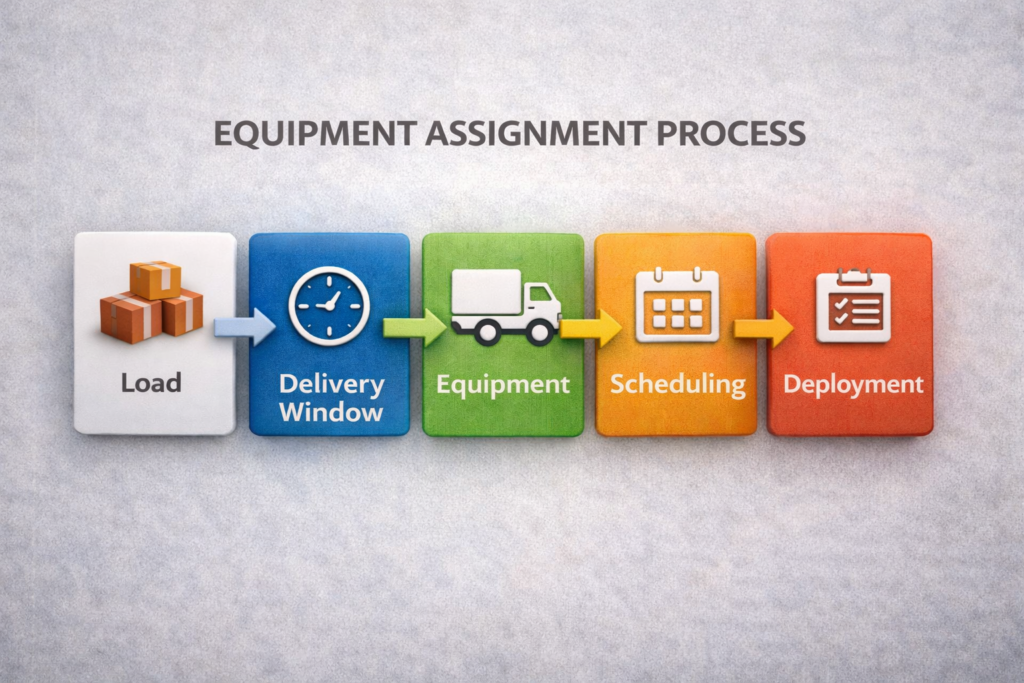

The Equipment Assignment Process: From Load to Deployment

GETTING A LOAD ASSIGNMENT AND TRIP PLANNING FOR NEW TRUCK DRIVERS | STEP-BY-STEP GUIDE FOR BEGINNERS

A concentrated assignment process turns dispatch from the reactive problem solver into the operational system that is repeatable and scalable.

Step 1: Load Qualification

The procedure for assigning equipment starts with the load qualification. Planning or dispatch teams determine the payload weight, dimensions, center of gravity, cargo sensitivity, and handling requirements. For the sake of easy decision-making, loads are often classified as standard, sensitive, oversized, or specialized.

Step 2: Delivery Window Mapping

As a utility, delivery windows translate into operational variables: allowable driving time, staging needs, dock wait tolerance, and risk of delay. This mapping step ensures consistency between schedule rigidity and equipment flexibility.

Step 3: Equipment Matching

At this stage, equipment matching evaluates transportation units against load characteristics and route demands. Axle configuration, braking capacity, suspension type, turning radius, and surface conditions are reviewed to determine the most suitable unit.

Step 4: Scheduling Equipment

Scheduling equipment involves synchronizing availability with maintenance cycles, driver assignments, and current utilization. This alignment prevents last-minute substitutions that typically reduce efficiency and increase fleet stress.

Step 5: Equipment Deployment

The equipment deployment process initiates after internal assignment rules and regulatory limits have been validated. This final step ensures execution follows a standardized logistics procedure that minimizes operational risk.

Equipment Assignment Errors and Their Operational Consequences

| Assignment Error | Immediate Effect | Long-Term Outcome |

| Availability-based assignment | Short-term convenience | Chronic inefficiency |

| Overcapacity usage | Higher fuel consumption | Accelerated depreciation |

| Misaligned axle configuration | Handling instability | Increased maintenance |

| Ignoring delivery windows | Missed appointments | Customer penalties |

| Reactive scheduling | Dispatch overload | Lower asset utilization |

Equipment Assignment Principles That Maintain Performance Over Time

Defined equipment assignment principles help fleets avoid short-term decisions that undermine long-term objectives. These principles support consistent resource allocation across assets.

The equipment assignment always requires the following rules:

- Never use max-capacity equipment for consistently partial loads.

- Specialized units must be reserved strictly for appropriate cargo.

- Axle configuration should align with stop frequency and surface conditions.

- Repeated operation beyond design limits must be avoided.

When these principles are respected, fleets avoid accelerated depreciation, rising maintenance exposure, and reduced availability of supply chain equipment caused by unplanned downtime.

Asset Utilization: The Hidden Multiplier

Freight Logistics and the Planning System Webinar

Asset utilization, when measured only by mileage, hides inefficiencies. True performance emerges when utilization is aligned with time, load matching, and schedule accuracy.

Proper allocation reduces operational risk by supporting:

- Fewer roadside violations

- Lower accident exposure

- Reduced emergency repairs

- Better compliance consistency

This approach shifts decision-making from reactive fixes to proactive planning, reinforcing logistics optimization at scale.

Capacity Planning as a Long-Term Advantage

Effective equipment assignment naturally feeds into capacity planning, ensuring that current decisions do not restrict future flexibility. When capacity planning is ignored, fleets often find themselves with misallocated assets during peak demand periods.

A disciplined assignment framework ensures that equipment deployment supports both immediate execution and long-term operational balance.

Final Thoughts

The act of assigning materials according to the specified loads and delivery windows is not merely a dispatch preference but a structural requirement for profitable trucking. Fleets that rely solely on availability sacrifice efficiency, reliability, and long-term margin.

By synchronizing equipment planning, load matching, delivery scheduling, asset utilization, and equipment deployment, trucking operations improve performance without increasing risk or workload. In modern truck driving, optimal equipment assignment is not a matter of luck — it is the result of disciplined processes applied load after load.

FAQ

What is the structured equipment assignment in trucking?

Assignment with a structured approach is just not based on availability alone, it's based on a standard operating logic. The load characteristics, delivery timing, and equipment capability are the factors that stop assigning before execution takes place, thus ensuring that mechanical limitations, scheduling constraints, and overall asset performance are maintained during the operation.

What is the risk in equipment assignment based on availability?

The availability answer only responds about if a machine is free and does not state whether it is the right one for the job. When assignments are made without the load profile, and delivery conditions taken into account, fleets usually realize, overly cascading delays, and see no gain in booking convenience as hidden wear, and other inefficiencies are greater than any benefits.

How would the set assignment rules save money in the long run?

The presence of formal allocation rules is a hindrance to resource waste through misuse. Matching equipment with initial expected operations first, fleets will incur lesser unplanned maintenance, shorter depreciation periods, and fewer operational disruption days that all bring profit margins down the line.

Is the assignment of the right different pieces of equipment the reason for a more reliable delivery?

Reckon absolutely. When devices are picked on a basis of overcoming delivery constraints, the performance becomes more and more predictable. Therefore, this induces fewer no-shows, better driver mood, and stable customer service level.

Does the formal assignment system inhibits dispatcher judgment?

An excellent framework accelerates decision-making rather than restricts it. The dispatchers deal with the exceptions, but the structure of boundaries makes it impossible for the continuous development of inconsistent practices that lead to negative impacts.

What is the impact of discipline in assignment on asset utilization?

By correcting the assignment of equipment, it enhances utilization because the equipment will work productively during the whole duty cycle. No more balancing equations, but rather doing beneficial work more of the time and less time wasted on idles, delays, or repairs.

Do assignment rules apply the same for all types of operations?

Nope. Local, city, and appointment-driven transportation require different considerations in contrast to long-haul transportation. Thus, the assignment logic needs to be modified according to the frequency of stops, maneuverability requirements, and schedule flexibility to be effective.

Who should set rules for equipment assignment?

Although dispatchers are mostly the ones who practice them the most and the equipment assignment rules should be a collective effort from fleet management, maintenance, and operations teams. This will ensure that decisions are founded on mechanical facts, scheduling realities, and practical execution rather than just theoretical constructs.