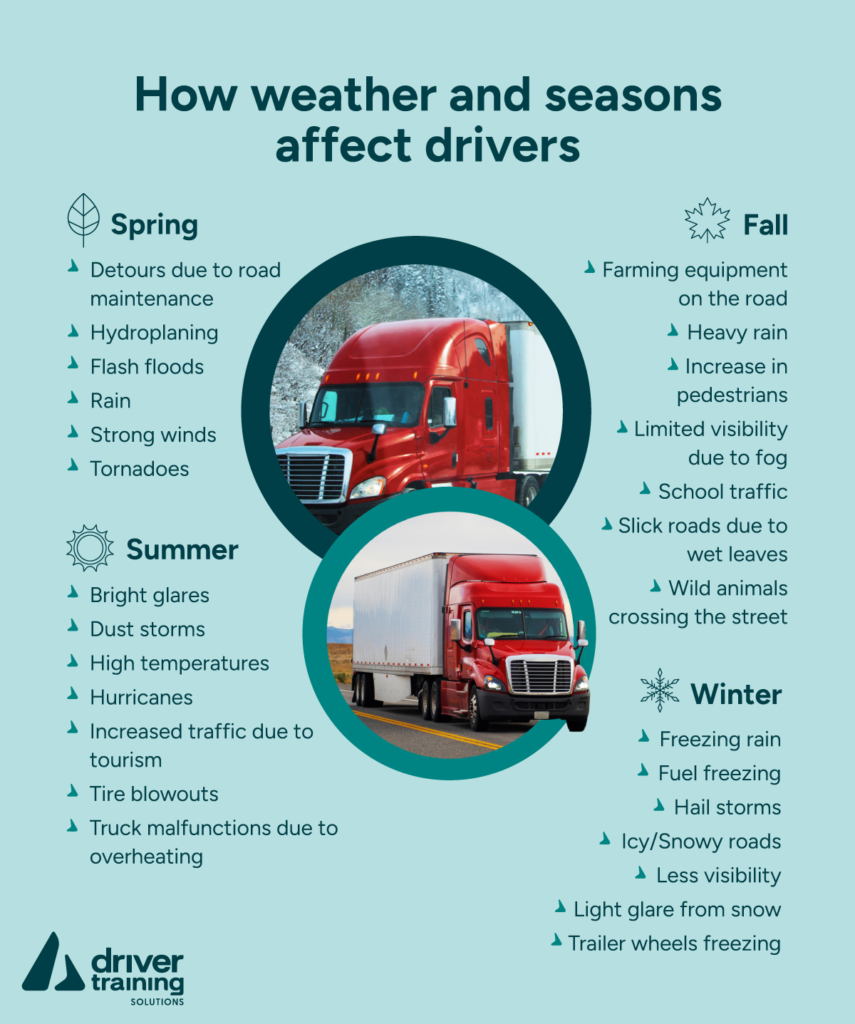

The impacts of seasons swinging between hot and cold are felt at the heart of the trucking business. The truck is a complex dynamic made of different systems, and no two systems have the same level of robustness. Wear and tear are expected under operational stress, but seasonal changes can encourage weaknesses to surface, break down, or, in the case of an inspection, result in failure.

Summer heat, winter cold, and long haul modes in fact do not create any mechanical problems; they only show the bounds of systems that were already running too close to their limits.

Seasonal readiness assessment is not merely an extension of regular truck maintenance practices. It targets the critical evaluation of how a heavy vehicle will perform when subjected to higher than normal environmental and operational pressures. Rather than waiting for the breakdown to occur and then responding to it, this pro-active approach emphasizes the listing of vulnerabilities that may occur before the resulting overheating, freezing, braking instability, or out-of-service roadside events take place.

In practical terms, this process acts as a structured seasonal prep layer that supports daily decision-making rather than reacting to failures.

This article outlines how to design a season readiness assessment template for summer, winter, and long haul operations, in particular by considering real-world driving conditions and real-world fleet maintenance constraints.

Seasonal Readiness as a Preventive Strategy

Truck maintenance scheduling is frequently based on mileage ranges or calendar days. This technique is effective for basic servicing, but it does not assess the stress from environmental factors. Seasonal readiness fills that gap, i.e., matching the preventive maintenance schedule with the conditions the truck is going to meet.

When applied correctly, it complements routine truck inspection processes rather than replacing them.

In practice, seasonal readiness is essential in three main areas:

- Exposing vulnerable systems earlier helps reduce unplanned roadside breaks

- Maintaining a stable repair scheduling by trading last-minute repairs with planned work

- Preserving safety through the operational margins stress level reduction

The heat literally multiplies demand on the cooling, because evaporative coolers must deal with the additional electrical load. The cold plugs batteries directly, tight rubber parts add friction, and air systems fail due to moisture contamination when components such as the air dryer are already operating near their limits.

For a long haul truck, these stressors accumulate faster due to sustained duty cycles and limited access to service.

Typical Seasonal Failures in Trucks

| Season | Typical Stress Factor | Affected Systems |

| Summer | High air temperature | Cooling system, tires, electrical |

| Winter | Cold weather | Air system, batteries, coolant |

| Long haul | Reliable work | Brakes, tires, sensors, cooling |

Systems That Define Seasonal Performance

Seasonal is a choice for overriding pneumatic impacts. The brake system, cooling system, tires, electrical components, and air system react differently to the changes in temperature, load duration, and environment.

With respect to maintenance, these systems often persist not through sudden trauma but by their tolerance edges narrowing. Seasonal readiness discusses the functioning of such systems under pressure rather than just physical inspections.

This perspective transforms a standard checklist into a targeted truck checklist aligned with environmental exposure.

The systems that fall prey the most to the changes caused by the seasons are:

- Heat-accumulating brake components or humidity-accumulating brake components

- Heat-maxing, cooling systems

- Tire pressure-related temperature tire-affection

- Corrosion and voltage instability of electrical systems

Summer Readiness: Managing Heat and Thermal Load

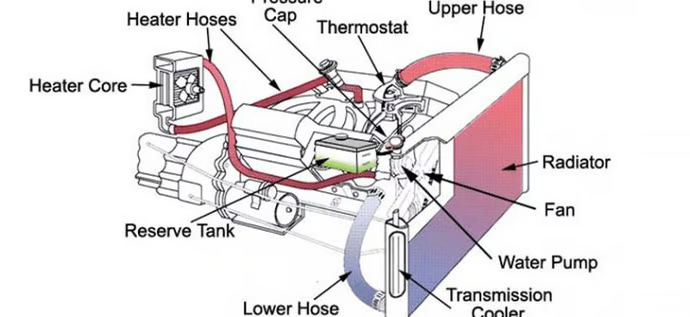

Summer readiness is primarily cooling and airflow efficiency improvement, which is basically controlling heat accumulation. Most of the time, overheating isn’t just a new-found crisis, but it is actually a gradual process where the margins of cooling are lost.

Effective summer readiness focuses on identifying these narrowing margins before temperature thresholds are crossed.

The heat coming from the environment frequently leads to needing more coolant, raising the electrical resistance and, consequently, accelerating corrosion. A long period of high idling also adds thermal stress to the engine and emissions systems while tires experience higher internal pressure and sidewall strain.

In summer operations, fleets most often miscalculate:

- The overall impact of idle engine heat on engine cooling

- Increasing of airflow restriction in radiator efficiency

- The rate at which tire pressure erodes under constant high temperature

Brake systems are also important. Hot-related brake fade will become more of a problem during summer descents and congested routes.

Summer Readiness Risk Areas and Outcomes

| Area | If Ignored | Likely Result |

| Cooling airflow | Reduced heat dissipation | Overheating |

| Tire pressure | Excessive expansion | Blowouts |

| Electrical terminals | Accelerated corrosion | Charging issues |

| Brake heat tolerance | Fade under load | Reduced stopping power |

Winter Readiness: Cold Tolerance and Moisture Control

Winterzation does the opposite thing, it makes sure that the system works properly at temperatures below the optimal operating range. Winter breakdowns are often sudden and cannot be fixed, therefore, drivers have little opportunity for making the corrections once they are already on the road.

Proper winterization requires special attention to moisture control and electrical resilience.

When it gets too cold, the battery fails to output enough power, the air system recovers more slowly, and there is a risk of freezing moisture inside valves and lines. Rubber materials become stiff, seals lose flexibility, and coolant systems turn vulnerable if coolant freeze protection is insufficient.

From an operational view, winter readiness is mostly about preventing:

- No-start situations during cold mornings

- Frozen air lines and delayed brake response

- Coolant-related engine damage

Winter Readiness Focus vs Safety Impact

| System | Winter Risk | Safety Impact |

| Air system | Moisture freezing | Brake malfunction |

| Electrical | Reduced battery output | No-start |

| Coolant | Insufficient freeze protection | Engine damage |

| Tires | Loss of flexibility | Reduced traction |

Top 10 Tips for Winter Trucking Prep! ❄️ 🚚

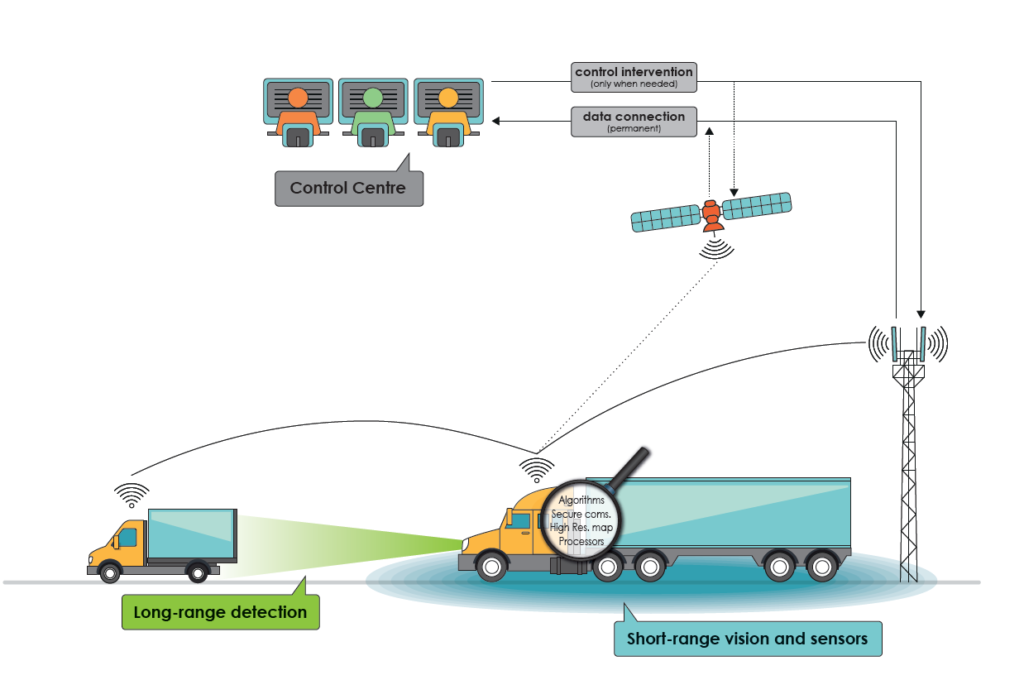

Long Haul Readiness: Sustained Stress and Operational Endurance

Long haul operations are a mix of both summer and winter stress, with the exception of time being a critical factor. Long haul runs are more prone to failures, as they multiply issues due to remoteness, decay, and unbroken operation time.

The idea of long haul readiness is based on stamina, meaning systems must perform consistently over thousands of miles without decline. For a long haul truck, even minor imbalances can evolve into major failures.

The long haul vulnerabilities are:

- High brake wear imbalance

- Tired tire casings

- Cooling systems not working right under constant load

- Electrical sensors triggering derates far from service point

Maintenance should be planned in a preventive manner as the service intervals, which are purely based on mileage, may not represent the real operating conditions.

Routine including Seasonal Readiness in Daily Operations

Assessing season readiness for a truck is most effective when not being single seasonal events but instead becoming a part of daily operations. Instead, they should notify pre-trip inspections and maintenance scheduling decisions.

This alignment strengthens both preventive maintenance planning and roadside truck inspection outcomes.

Drivers act as the first detection layer, noticing rising temperatures, slower air recovery, or electrical inconsistencies. Maintenance teams then act before these issues develop into failures.

Such coordination helps reduce emergency repairs and improves overall fleet reliability.

Cutting OOS Season Profiles by Tackling Each One Early

Out-of-service spikes synchronously correspond to the first extreme temperatures of the season. The heat wave shows weakness in the cooling system, the freeze exposes air system vulnerabilities, and long haul journeys multiply mechanical stress.

Early seasonal assessments directly reduce the likelihood of an OOS spike by addressing predictable fault patterns.

Season readiness assessments therefore contribute to better compliance and operational continuity.

Vehicle Safety is Linked Through Correct Season Alignment

Vehicle safety improves when the truck is thoroughly prepared for the environment in which it is expected to operate. Seasonal readiness is a strategy for reducing risk, but it must also be understood as maintaining operational margin.

Prepared trucks give drivers better control, predictable braking behavior, stable engine cooling, and fewer unexpected failures, directly supporting safe truck operation.

Final Note

Templates for season readiness assessment are effective because they apply targeted, season-specific interventions, from summer heat control to winter failure prevention and long haul endurance planning.

In trucking, seasons do not cause breakdowns — unprepared vehicles do. Systematic seasonal prep keeps trucks safe, compliant, and productive across every mile on the road.

FAQ: Seasonal Readiness Assessment for Trucks

What is a seasonal readiness assessment for trucks?

A seasonal readiness assessment is a systematic evaluation of how a truck will perform under certain environmental and operational circumstances. Unlike routine truck maintenance, it deliberately targets associated conditions such as heat, cold, and continued load, which can result in failures during the truck readiness, winterization, or long operation.

How is a seasonal readiness assessment different from a regular truck checklist?

While a regular truck checklist simply confirms the basic roadworthiness of the truck, a seasonal readiness assessment is more advanced, as it not only considers the bearable mechanical stress but also evaluates the system’s tolerance under stress. It is a perfect complement to the daily pre-trip inspection since it points out the vulnerabilities that may be visible only at extreme temperatures or after long duty cycles.

Why does the seasonal prep reduce roadside breakdowns?

The seasonal prep is the first thing to do to stop failures from happening that you can rely on. By the time you check your fleets for cooling capacity, air system moisture control, coolant freeze protection, and electrical resilience, you will have dealt with the very issues that cause roadside events and bring about inspection failures commonly.

Which systems are mostly influenced by seasonal changes?

The systems that are most affected during the re season and hot season changes include the brake system, cooling system, tires, electrical components, and the air dryer. These systems respond to outside heat and other factors differently thus they become important areas of concern during truck inspection.

How does winterization help in preventing out-of-service events?

Winterization can be a proactive measure that ensures a truck is protected against any cold snaps that may cause things to freeze like the air lines, weak battery output, and coolant damage. Proper moisture control and coolant freeze protection can help prevent the overuse of the OOS during wintertime inspections.

Is seasonal readiness important for long haul trucks?

Yes, it is strong tandem. The long-haul truck is subjected to the existing stress of working hard for long periods, which in turn, accelerates the clock on wear and causes small problems to multiply. The seasonal readiness program makes sure that the tire condition, electrical system, cooling the vehicle effectively, and braking balance are all fine throughout the journey.

How often should seasonal readiness assessments be performed?

Seasonal readiness assessments should be conducted before commencing a new season and should be repeated in cases of extreme temperature situations. For those fleets operating on long haul missions, the periodic reassessment as part of Preventive Maintenance planning are the right steps to take.

Can drivers contribute to seasonal readiness beyond pre-trip inspections?

Drivers have a major role to play such that they will reduce the costs of repairs and prevent total or partial breakdowns by doing this early interventions. This feedback indeed helps the fleet maintenance teams to detect and fix the issue before the vehicles breakdown or fail to comply.

Does seasonal readiness replace preventive maintenance?

No, they are together. Seasonal readiness is a preventive maintenance strategy that is different from others because it is relied upon to determine the causes of wear and tear, while seasonal readiness is concerned with prioritizing the maintenance based on the environmental exposure and the level of operation.

How does seasonal readiness improve vehicle safety?

Seasonal readiness supports vehicle safety through the preservation of the operating margins. Trucks that are prepared for either heat, cold, or sustained loads are more predictable in braking, engine cooling is stable, and fewer unexpected failures all of which lead to safer driving conditions draw the picture.