Introduction

It all boils down to numerical analysis in the trucking industry. Although technology, as well as safety and regulatory compliance, have their place, the fleets’ lifeline is embedded in the margins that are expressed in cents per mile. This is the reason why the issue is not which upgrades are the latest, but which truck model upgrades are the best in the shortest period and with maximum reliability.

When it comes to fleet upgrades in North America, the main winners on the list of financial savings are: auxiliary power units (APUs), truck cameras, tires, and telematics. Every single upgrade touches an area of the fleet’s performance such as the reduction of fuel costs, preventive maintenance, driver behavior, or the lifespan of the asset.

Having a grasp of the actual influence of these upgrades on the day-to-day operations is the line between running after the newest available technology and accumulating money in a sustainable way each year.

The Single-Mindedness of ROI in Fleet Decisions

Financial awards are not given for the management of fleets based on assumptions. In a very short time, an upgrade that is not able to cut the cost per mile, downtime, or repair exposure transforms into a cost item and it is recognized as such.

Common Traits of High-ROI Improvements

- They deal with daily persistent costs

- They diminish unexpected repairs or events

- They assist in the prolonged planning of vehicle maintenance

The explanation is quite simple. When these features are realized, the return on the investment can be calculated on the basis of operating cycles and not years.

APU: The Fastest Return on Investment through Fuel and Engine Protection

An auxiliary power unit is one of the clearest examples of an upgrade with predictable APU ROI. By powering climate control and electronics without idling the main engine, APUs directly cut idle fuel consumption and engine wear.

Where APU ROI Comes From

- Substantial savings on fuel from idling reduction

- Fewer engine hours than usual, which leads to longer service intervals

- Improvement in energy efficiency while resting

APUs have the additional benefit of contributing to lower repair cost through the reduction of stress on the engine and the emissions systems from a vehicle maintenance standpoint. Fleets engaged in long-haul or sleeper operations typically realize payback periods of 1-2 years, with some, in severe climates, even shorter.

Cameras: R.O.I. Based on Risk Reduction, not Surveillance

Truck cameras are frequently perceived as monitoring tools rather than financial assets. The truth is that the primary force of the camera’s ROI is risk mitigation and, of course, the cost avoidance.

How Cameras Pay for Themselves

- Lower accident-related costs

- Faster claim resolution and disputation prevention

- Better warranty recovery and insurance negotiations

Fleet Camera System | How To Use Video Telematics To Your Advantage

Cameras are also implemented to drivers’ performance as they lead to fewer deviations such as harsh braking, unsafe lane changes, and collision density. Consequently, with time, the reduction in the number of such events translates into the savings made and thus leads to more predictable operating costs.

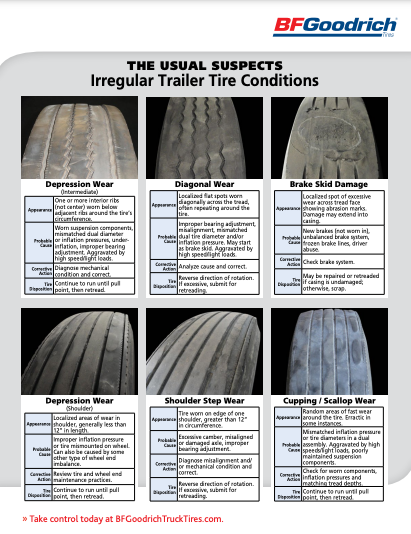

Tires: On The Way to Lower Cost per Mile by Controlling Tire Wear

As one of the most overlooked contributors to the operating cost, tires can be. Tire wear is closely related to the overall fuel economy, driver’s comfort, and suspension condition.

Why Tire Upgrades Pay Off Quickly

- Fuel savings by lowering rolling resistance

- Reduction of uneven wear due to and alignment

- Lower cost per mile for longer replacement cycles

The financial benefits become evident immediately when tire programs are compounded with fleet alignment and routinely conducted inspections. Proper tire management is also an advantage in the fiscal respect as tires are the cause of vibration-related damages.

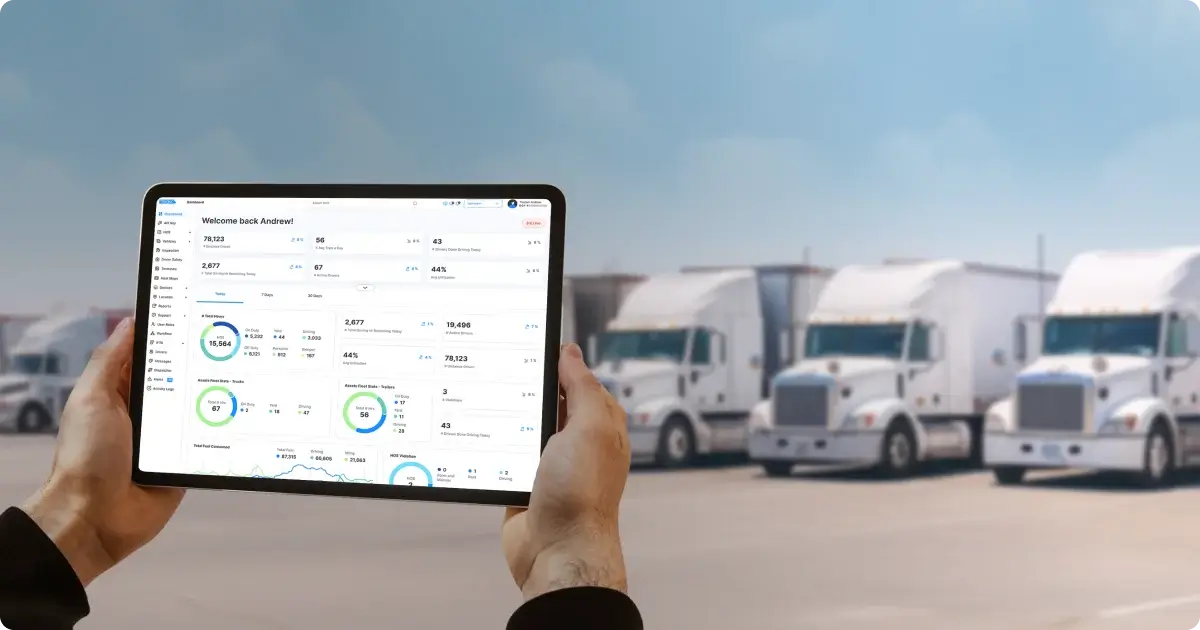

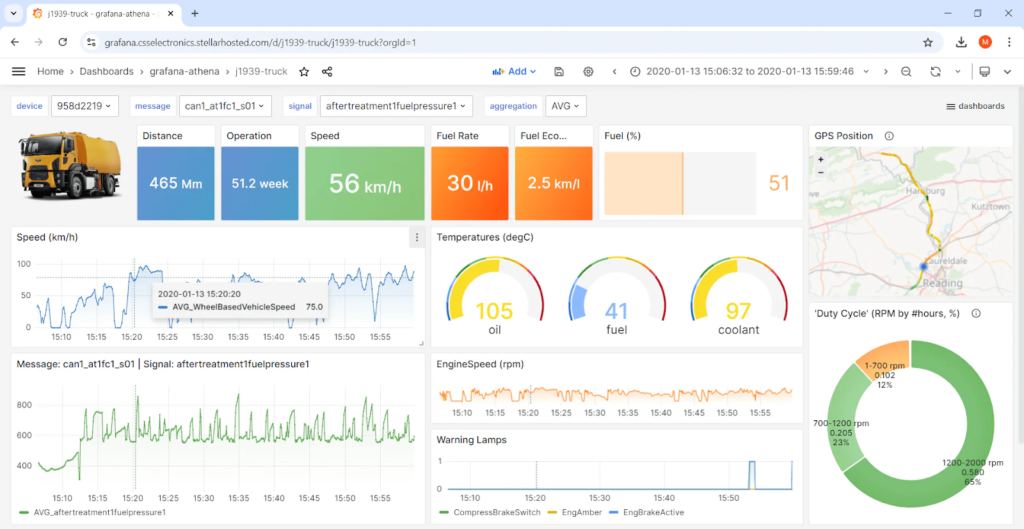

Telematics: The Return on Investment through Visibility and Predictive Control

Every telematics system first appears as a smart technology, though its real cash flow comes from telematics R.O.I. by means of prevention.

The benefits of video telematics in fleet operations

Where Telematics Delivers Value

- Being the first to notice about mechanical problems

- Avoiding breakdowns through preventative maintenance warnings

- The integration of scheduling maintenance programs with software

Telematics, by curbing the unexpected breakdowns, has been the major influencer to the decrease in the downtime. In the long term, the data-driven approach stabilizes the operating cost and keeps the fleet aligned.

Comparing Payback Speed Across Upgrades

| Upgrade | Primary ROI Driver | Typical Payback Speed |

| APU | Fuel savings, engine protection | Fast |

| Cameras | Risk reduction, claims defense | Medium |

| Tires | Reduced wear, fuel efficiency | Fast |

| Telematics | Downtime reduction, maintenance control | Medium |

Systems that cut the day-to-day recurring expenses are the ones which tend to pay back the fastest, while telematics, through their data character, bring value over time.

Preventive Maintenance as an ROI Multiplier

Preventative maintenance does not create an ROI independently but it intensifies the return from other upgrades.

Telematics along with APUs and tire programs create a framework that ensures fleets can deal with small issues before they grow. This lowers the repair costs, smooths the service schedules and prevents the emergency downtime.

Once a fleet opts for a reactive repairs-based approach, the overall ROI is often considerably delayed, regardless of whether they are using premium equipment.

The Financial Layer of ROI: Measuring ROI as a System Rather Than Components

Taking into account the measurable impacts of the fleet components independently, the fleet-decision making processes are not done in an absolute vacuum. From a fleet management viewpoint, the real return on investment occurs when upgrades are seen as a part of the bigger operational system and not only as isolated improvements.

ROI Cameras as the Source of Cost Stability

The financial value of cameras ROI becomes especially visible over time.

Telematics ROI and Predictable Operations

Telematics ROI is not always evident at first, but the return increases over time.

Tire Wear Control as a Silent Cost Lever

Even though tire wear is mostly overlooked, it is one of the key factors that affect the operational economics positively.

Operational Alignment and Long-Term ROI

The excellence in finance occurs when the elements in the system boost each other.

Downtime v Cost Effects: The Hidden Trade-Off

Downtime is evidently more than just a simple figure; it has consequences.

Downtime Reduction Drivers

- Cameras stop accidents from occurring thus preventing delays

- Telematics encroach on roadside breakdowns

- Tire management curtails blowouts

Driver Performance and Upgrade Synergy

Technology does not take the place of drivers – it dictates passenger behavior.

Behavioral Impact Outcomes

- Reduced use of breaks

- Longer life for tires

- Less repair cost from accidents

Fuel Savings that Extend Beyond Idle

Fuel saviors are not confined to APUs alone:

- Telematics provide route optimization and idle time management

- Tire upgrades lead to reduced rolling resistance

- Cameras help cut down detours after incidents

Upgrade Prioritization by Operation Type

| Operation Type | High-Priority Upgrades | Secondary |

| Long-haul OTR | APU, Telematics | Cameras |

| Regional | Tires, Cameras | Telematics |

| Dedicated | Telematics, Preventive Maintenance | APU |

| Owner-Operator | Tires, APU | Cameras |

Final Words: ROI is Built Mile by Mile

The truck upgrades that yield the quickest returns are not always the most expensive or the most complicated.

APUs, cameras, tires, and telematics, all are important, but the best results come from aligning the upgrades with the management strategy and real-world use.

In the trucking industry, ROI is not just a concept in theory; it is a tangible measurement taken mile by mile and truck by truck.

FAQ: Fleet Upgrades, ROI, and Practical Decisions

Which of the upgrades provides the fastest return on investment among trucks?

In most fleet operations, APUs and tires are generally the fastest return on investment because they save the daily recurring costs like fuel consumption, idle hours, and tire wear. These cost savings are immediate, measurable, and directly reduce the cost per mile, which is why these upgrades are often classified as high ROI solutions.

Are truck cameras a financial product or only a security instrument?

Truck cameras, primarily through risk reduction, are a means of generating ROI with cameras. With fewer accidents, speedier claims processing, and better driving, repair exposure decreased along with the insurance costs; therefore, cameras are a financial stabilizer and not a surveillance tool.

How is telematics ROI different from other changes?

Unlike other upgrades, the benefits of telematics are more likely to be realized over a longer period of time than immediate ones. Its merit is the result of the decreased time of operation, the pro-active service of the equipment, and of the better decision making of fleet managers who, supported by maintenance software, can prevent breakdowns and extend the asset’s life.

Can tire upgrades bring about a change in the annual savings?

Of course. The right choice and the right approach of the tire strongly affect the tire life, fuel consumption rate, and the suspension system. This, in turn, results in higher annual savings through the shift of the tire replacement cycle and avoiding repairs caused by vibration.

Are these upgrades only effective when working together or can they work alone?

Individually, each upgrade provides some value, but the greatest amount of return on investment appears when the system of APUs, cameras, tires, and telematics works together. As a team, they manage to improve driver performance, maintenance timing, and operational predictability across the full asset lifecycle.

Is it more important to do preventive maintenance than it is to upgrade equipment?

Preventive maintenance does increase the value of upgrades. Without maintenance discipline, high-ROI equipment may not meet the expectations as a result of delayed repairs or service cycles being reactive.

Which is the bone of contention; upgrades or the time to downtime?

Downtime reductions are achieved through several routes: accident delay caused by cameras, early mechanical detection by telematics, tire programs keeping blowouts at bay, and APUs reducing idle-related engine stress, all of which contribute to reduced downtime.

Are these upgrades a one-size-fits-all solution for owner-operators too?

Owner-operators, who are the recipients of the most benefits from tires and APU, as far-targeting fuel savings and comfort is concerned, are the ones who choose these items the most. Cameras and telematics still have remained value added but are ordinarily adaptively accepted based on the particular style of operation.

Can fleet upgrades even increase the truck’s resale value?

Of course. Equipment that is documented by telematics and having met established maintenance core best practices improves the long-term protection on the asset by supporting warranty recovery and clean vehicle management during resale or trade-in.

What’s the biggest blunder fleets make when it comes to upgrading?

The major error is the over-upgrading without a technology-customer operational need alignment. Efficient fleet management is about the choice of upgrades that specifically target the reduction of costs or downtime rather than it is about a trend-following movement.