In trucking, profit is one of the confusing realities. Most operators see it as a matter of better rates, longer runs, or new equipment. In reality, however, profit is more often aligned with the right elements – the machinery, the market niche, and the operational fact of the matter. Misalignment is the cause of even a full truck running slowly.

This true case case is based on a trucking company that was not failing but was also not thriving. By redefining its target niche and rebuilding its specification strategy around that niche, the business achieved a measurable profit increase without adding trucks, drivers, or risk exposure.

What makes this a real-life case study is not the numbers themselves, but the sequence of small, practical decisions behind them.

This is not a story of chance or extraordinary timing. It is about intentional specification driving the business profit, income, and long-term developments in the company; that is the essence of the story.

At some point, it became clear that choosing specification mattered more than chasing the next available load.

The Industry Context: So Many Trucks Performing Poorly

A generic axiom is traceable in the truck driving industry. Transporters that quit the market usually enter it with a general configuration truck that is made to “tackle any issue”. This strategy, especially in the early days, feels like laying a strong foundation. Using the flex approach seems like making a safe bet, it is like a hedge to a risk.

Flexibility has a cost that is not apparent.

A truck’s potential productivity costs go down significantly in any particular market. The alternative is to carry excess weight, lose more fuel than is necessary and incur maintenance costs not directly related to revenue. These inefficiencies are a disadvantage in the long run, particularly in the niche market that are highly competitive and where profit margins are tight.

True niche profitability only appears once a truck stops trying to serve every possible scenario.

The company’s situation is this case study’s starting point.

The Business at the Starting Line

The operation at the focal point of this case study was a one-truck business located in the Midwestern part of the USA. The owner-operator was a seasoned industry player and had extensive knowledge regarding the freight markets. The truck was fully paid for, in mechanically good shape, and was steadily booked with jobs.

At first glance, it looked like a viable trucking startup that has overcome the most critical surviving period.

However, the financial results were quite telling.

Key financial signals

- Net margins were stagnant year after year

- Maintenance costs were on a rise

- Fuel prices were unpredictable

- Unexpected downtime was more frequent

Despite remaining active, the business profit would not scale up.

What followed looked less like expansion and more like cautious business growth.

Initial Assumptions — and Why They Were Wrong

During his first thoughts, the operator was blaming external factors. For example, brokers were seemingly less reliable, and the market rates were lower. There was the feeling of more competition. These were the explanations that were given often but were partial at best.

A closer case study analysis showed that revenue was not the issue.

Careful analysis of the case showed that revenue was not the issue. It was the cost structure that was problematic.

Original product specification

- A large engine made for a long-haul truck

- A full sleeper that was seldom used up to its full capacity

- Axle ratios that were made for highways, not for loops

- Excess weight and complexity that went beyond operational needs

Hence, the specification was right but the tracking was inefficient.

In this context, achieving profit meant reducing friction rather than increasing effort.

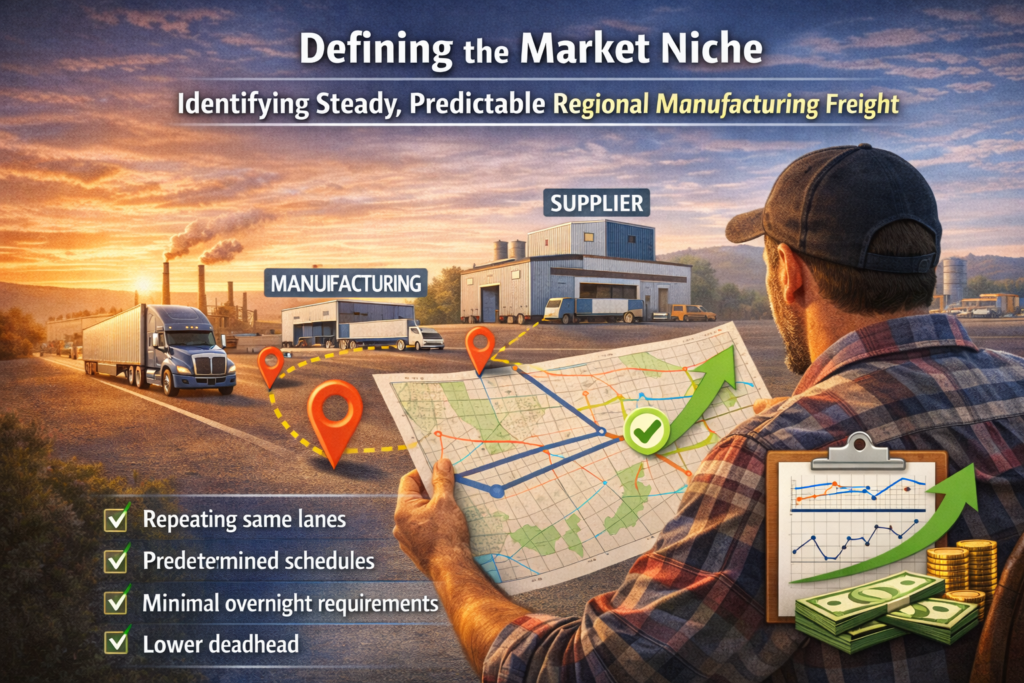

The Turning Point: Defining the Market Niche

The shift initiated by a strategic retreat. Instead of soliciting more loads, the operator examined the historical data for the patterns.

One significant detail was a complete overlook.

Niche Down & Haul Profits! Top Trucking Niches for Success in 2024

The most steady and least burdensome loads were a special niche market: regional manufacturing freight moving between plants, suppliers, and distribution centers within a predetermined distance.

Characteristics of the niche

- relating to the same lanes repeatedly

- working with predetermined schedules

- minimal overnight requirements

- a lower percentage of deadhead

However, in order to profit from this niche, the operator had to change their mind-set.

The increased profit did not arrive instantly, but it stayed once the operation stopped resisting its own structure.

Why Niche Definition Comes Before Equipment

Many operators adopt the practice to first optimize the equipment and thereafter, seek for freight that suits. This business chose to go against that logic.

The operator specified the market niche as the primary thing and then asked the pivotal question:

What exactly is the appropriate specification for this kind of work?

The change of mind was total. The operator, in place of the question of which truck was the most impressive one, refocused the attention to the niche specification – the type of configuration that would maximize efficiency in that niche.

This stage quietly turned into an exercise in specification selection, not a dramatic overhaul.

Specification Strategy: From Generic to Purpose-Built

The next move was the attached specification to the intent.

Every part of the truck was subjected to the scrutiny of the daily demands by the niche market. If the part did not directly foster revenue generation or operational efficiency, it was questioned.

Key specification decisions

- Picking a middle-weight engine matched to regional torque needs

- Instead of balancing efficiency at modest speeds devised axle ratios

- Reducing sleeper size resulted in less weight, and thus improved maintenance complexity

- Enhancing maneuverability for plant yards and city ingress/egress

This was not about cutting costs but it was a deliberate choice of specifications.

Generic vs Niche-Specific Specification Strategy

| Category | Generic Setup | Niche-Optimized Setup |

| Engine size | High horsepower | Right-sized for load |

| Axle ratio | Highway-biased | Regional efficiency |

| Sleeper | Full-size | Compact |

| Vehicle weight | Higher | Reduced |

| Fuel efficiency | Moderate | Improved |

| Operational fit | Broad | Targeted |

Implementation Without Expansion

So, we have come to the most important lessons of this case study – things that did not change.

What did not change

- The company did not acquire any more trucks

- It did not hire drivers

- It did not go to chase premium contracts

The only thing it did was hone its specification strategies and realign its operations tightly around a defined market segment.

The decision was to limit risk and also improve the bottom line, a rather rare combo in the trucking industry.

Operational Results: The First 90 Days

The results of the new specification were observable right from the start.

Fuel efficiency saw a rise without any changes in routing. The intervals for maintenance also stabilized. The wear on tires normalised. There was a decrease in time that was used in yards due to easier dock access.

The truck hardly felt like “overbuilt” anymore for the tasks. It just felt built right.

This alignment diminished frictions – the small inefficiencies that through the adding and re-adding of profit can break statements.

Financial Outcomes: Measuring Profit Increase

After 6 months of the change, the company opted to do a thorough financial reassessment.

The results were straightforward, and there was no room for contradictions.

Financial Performance Before vs After

| Metric | Before | After |

| Average MPG | Lower | Higher |

| Maintenance cost | High | Reduced |

| Deadhead miles | Frequent | Limited |

| Monthly net profit | Flat | Increased |

| Cash flow stability | Volatile | Predictable |

The rise in profit did not arise from higher rates. It was realized through efficiency and predictability, the two pillars of firm growth that are sustainable.

Why Specification Beats Scale

The case study shows an important moral, that is, the process of growing bigger through scale often does increase the inefficiencies. But growth through correct alignment is the means of their removal.

Numerous operators are in the habit of increasing their profits by adding up trucks or exploring new territories. In this case, the addition of profits was done by the company not diversifying but narrowing down their focus.

Through the right specification, the business serving a clearly defined niche didn’t only increase its margins, but it also hedged away a part of the volatile market.

Psychological Constraints with Selecting the Right Specification

One primary reason for the neglect of this methodology is that of psychology.

People think of large blocks, tops, and widgets as being superior. Their presence constitutes wealth. A reduction in the size or the burden of the duties can seem as non-progress.

Conversely, choosing the right truck for a niche is an indication of progress and maturity, not of limitations.

This operator shifted the paradigm by seeing the truck as a tool not a brand. The mental setting they adopted opened the doors to better decisions.

Specification Focus by Market Segment

| Market Segment | Specification Priority |

| Long-haul | Comfort, fuel range |

| Regional | Balance, agility |

| Urban | Compact, idle efficiency |

| Dedicated lanes | Consistency, low wear |

Long-Term Business Growth

Above and beyond the immediate monetary profits, the new specification strategy forestalled future conflicts.

An organized schedule increased predictability. Less fatigue is associated with increased focus. Maintenance turned from being a reactive to a proactive procedure. Clearly operating, these factors supported long-term business success.

The operator was not just a reactive problem solver; it was a manager now.

Generating Revenue Obliterating Volume Chasing

One of the most strides seen in this truly-live case study is that revenue generation does not demand continuous growth.

By matching specification choice with the right market niche, the company could grow profits without putting in more time and effort.

This kind of practice leads to lower stress, fewer risks, and better decision-making which is a rare combination in trucking.

Key Outcomes of Specification Alignment

| Outcome | Impact |

| Niche clarity | Reduced volatility |

| Right specification | Lower operating costs |

| Focused strategy | Sustainable profit |

| Operational alignment | Business stability |

Final Conclusion

The case study shows that some of the most profitable choices that are made in the trucking industry rather happen before the truck is already on the road.

Choosing the right specification for a clearly defined niche market is more than just technical detail; it is a strategic advantage.

When the equipment, the market segment, and the operational reality are in sync, profit is a natural consequence and not an ongoing struggle.

In trucking, success is not about doing a lot of things.

It’s about doing what fits — and doing it on purpose.